Cake gel is that magic ingredient that works wonders for the production of soft cakes. With its powerful whipping abilities – it boosts volume, softness and adds a wonderful mouthfeel. It optimises the overall baking result, streamlines production and can reduce the recipe cost. Learn how a Cake Gel makes a stronger end-product, and why the Aromatic Cake Gels are chosen by industrial cake manufacturer worldwide.

This is how a Cake Gel works

A Cake Gel contains a mix of carefully selected emulsifiers. It promotes the dispersion of one liquid into another non-mixable liquid. A Cake Gel also stabilises the bubbles in the batter, which helps the cake to receive a nice improved volume, a perfect moist and even crumb. It also adds softness and a perceived freshness to the cake.

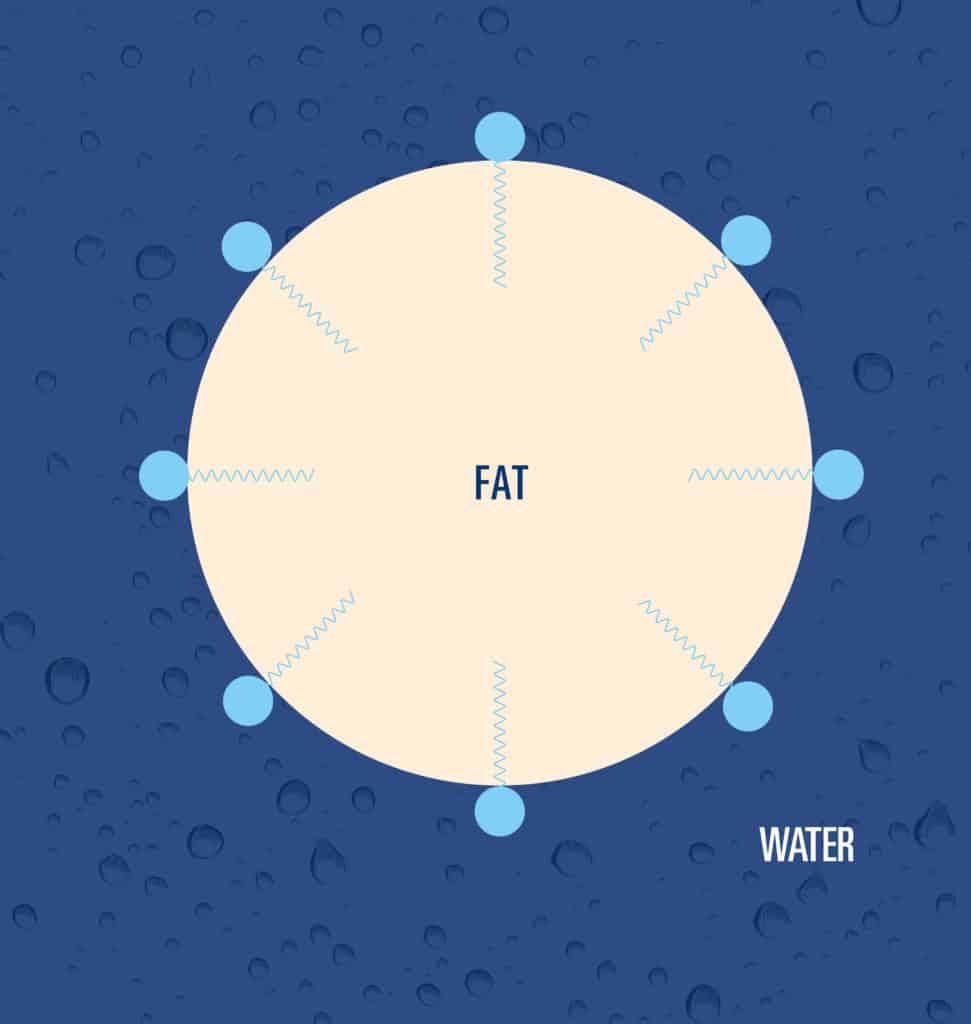

So, let’s go technical. The tail of the emulsifier molecule has a nonpolar end, while the head of the emulsifier molecule is instead polar. The molecular structure has both lipophilic (fat loving) and hydrophilic (water loving) properties, where the head is water loving and the tail is fat loving.

When adding an emulsifier to a cake batter it ends up in a surface layer between the water and fat, where it lowers the interfacial tension between the oil and water phases (a state called emulsion). The improved emulsification of fat and water in the cake batter together with increased batter viscosity stabilises the batter significantly. It provides great conditions for an outstanding baking result, and a streamlined and reliable baking process.

Why choose an Aromatic Cake Gel?

The Aromatic Cake Gel is an alpha gel (α-gel) emulsifier in a paste form. Compared with powder-based emulsifiers it has great functional benefits in having a water-rich structure. It forms a film around the bubbles and prevents them from breaking. It also decreases the density and increases the incorporation of air into the batter.

The gel has a higher concentration of active monoglycerides compared to powder products, which improves the perceived freshness of the cake. Recipes using powder emulsifiers often needs more moisture and a larger proportion of eggs to obtain the same end-result.

Also, the gel offers lower dosage levels, it’s easier to mix with other ingredients, it activates the functional ingredients immediately and shortens the mixing time. Furthermore, it saves valuable time as it allows for the all-in-one method and unnecessary steps, like gel preparation, can therefore be avoided.

A Cake Gel is in many ways a more practical and cost efficient alternative.

Seven reasons for why industrial cake manufacturers favour Aromatic Cake Gels

Bakels has produced Cake Gel for the baking industry for several years. A wide range of Cake Gels meeting various conditions, demands and local regulations has been developed during the time. For example, the assortment of today includes pumpable Cake Gels, palm-free products as well as Halal and Kosher alternatives.

Let us share seven reasons for why industrial cake manufacturers worldwide choose a Cake Gel from Aromatic.

- Cakes with great volume

Whipping the right amount of air into a batter is fundamental to achieving the right volume in the baked product. The Aromatic Cake Gel improves the batter whipping properties by aiding and stabilising the foam. More bubbles can be created, which boosts the volume and the appearance of the baked cake. - A reliable stability

The Aromatic Cake Gel stabilises the batter during baking and the baked product during cooling, due to the surfactant properties. This results in a more reliable baking process, it standardises the quality of the cake and ensures the consistency of every batch produced. - A smooth texture & symmetry

The increased number of bubbles that the Aromatic Cake Gel provides the baked goods with a soft and light texture. The cake will also have a fine and regular crumb structure and a nice even surface. Together this provides an appealing mouthfeel that enhances the eating experience. - Long living freshness

The Cake Gel also contributes to a perfect moistness in the baked good, which prolongs the perceived freshness of the cake. This is because the gel helps to retain the moisture and reduce the rate of starch retrogradation. Enjoy a softer product that will keep fresh for a longer time and will therefore reduce waste. This is good for the economy and the environment as well. - Fat dispersion gives optimum mouthfeel

The Aromatic Cake Gel disperses fat in fine, discrete particles throughout the batter. If the fat is not optimally dispersed, large particles of fat may be present and result in a greasy batter. Fine dispersion of the fat is important for ensuring a feeling of quality of the baked product. - Enables modern machinability

Traditionally, batter mixing has been a multistage operation, but today most commercial operations prefer a simplified one or two stage operation to streamline the production. The Aromatic Cake Cel all-in-one-method is suited to enable this kind of modern machinability. - Economic benefits

Thanks to a high concentration of monoglycerides only a very small dosage is needed, which means a low cost per use. Furthermore, by using the Aromatic Cake Gel the egg content can be reduced, which often stands for a considerable part of the total recipe cost. Add to that, the minimised risk of production fails with less waste costs.

What to use in

Emulsifiers in general are an important functional ingredient in food processing. In most large scale productions it is a necessity for a reliable production and consistent quality.

The Aromatic Cake Gels can be used in all sorts of soft cakes. For example, in sponge cake, muffins, Swiss rolls, layer cakes, and pound cake. It can also be used in fillings and in the production of ice cream.

Among the most used cake gels in the Aromatic range are Colco, Jilk and Coba. They can be used in industrial or small-scale production and is available in packages from 5 kg up to 1000 kg. For an automated production, a pumpable cake gel is to recommend. It can be delivered in tanks or in a recyclable system, that we call Easy Flow.

The Bakels product team is always at hand to help choosing the most suitable product based on application, condition and price. Do not hesitate to ask a question.

Complex to produce. Very easy to use.

All ingredients used in our Cake Gels are of vegetable origins and the material is extracted from oil-rich plants. We use distilled monoglycerides as a base in the Gels and always carefully select ingredients. This is how we can utilise and control the full potential of the emulsifier.

Producing stable Cake Gels is challenging where many different parameters need to be controlled in detail such as composition, quality of raw materials, temperature and hygiene. With our solid experience, we know exactly how to control and monitor these parameters, creating a perfectly user-friendly product.

The Aromatic Cake Gels are developed and produced in Sweden, where we have a modern and large-scale production that meets all hygiene requirements – certified with the highest ranking according to BRC. The production capacity of producing cake gels is 6 000 ton annually.

We would like it to be easy to implement our ingredients. Our team of product and production technicians are always at hand to adjust recipe formulas and support with implementation on the production line.

And did you know that we give a satisfaction guarantee for the first batch as a new customer? Please contact us and we will tell you more!