TTT – A NATURAL HEAT TREATMENT PROCESS WITH CEREALS FROM SWEDEN

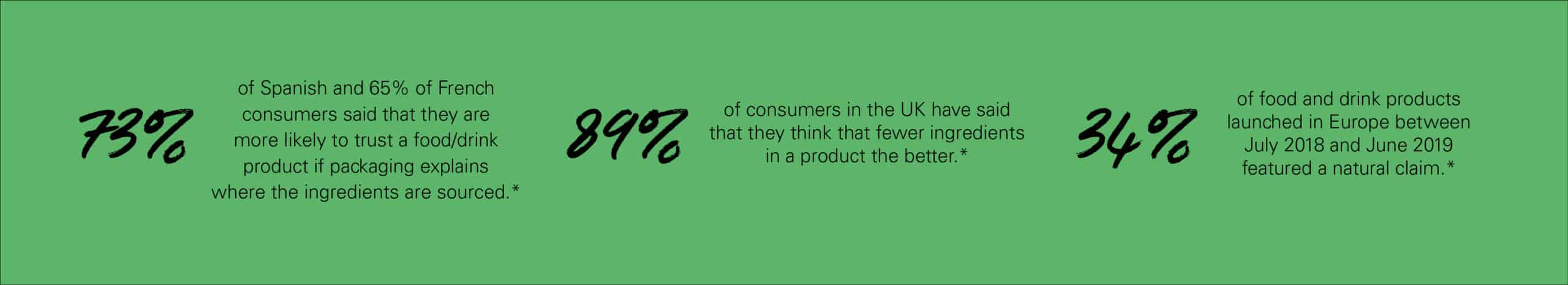

The consumer requests products that are based on natural ingredients and with a short ingredient list. An increased focus on health and a demand for transparency are the foundations of the consumer’s choice. Today’s consumers want products with a clean label more than ever before and expect the food and bakery manufacturer to deliver it. They are even willing to pay a higher retail price for products made with ingredients they recognize and trust.

With our natural and innovative TTT products made from pure wheat, rye, barley and oats, it is possible for you to prolong freshness, improve softness and extend shelf life of your bread assortment, without adding any E-numbers.

Removing ingredients that strengthen, stabilize and preserve food creates a challenge to maintain food safety, long shelf life for your bread and other bread enhancing qualities. With TTT you can ensure that the qualities of your bread remains. In fact, using our TTT products gives your bread assortment even more benefits that the consumer values highly.

A NATURAL HEAT

TREATMENT PROCESS

The TTT process is a completely natural process for heat treatment of cereals, which does not apply any chemicals or other additives during the processing of the raw materials. The process parameters TTT represent the Swedish words for Time (Tid), Temperature (Temperatur) and Pressure (Tryck).

HIGH WATER

ABSORPTION CAPACITY

TTT products have a very high water absorption capacity; up to two and a half times their own weight. This makes more moist and less crumbly bread because a greater amount of the starch in the flour is being bound up. The higher moisture content also gives greater dough yield.

SOFT VALUES

• The products are all of pure vegetable origin and free from GMO.

• Enables you to offer clean label products.

• Gives multiple health benefits to your baked goods, such as high- fibre, natural vitamins and minerals.

PRODUCT VALUES

• Having a water binding capacity five times higher than conventional flour, the bread’s moisture and softness maintain.

• Enhances the quality of thawed frozen products, due to the fact that there are many more water molecules vibrating, giving the finished bread a higher quality.

• The products are free from enzymatic activity.

• Provides reliable dough consistency throughout the baking process.

• Can replace milk in your recipe as oats contains more fats than other grains (Halfie M160).

• Thanks to the TTT process, the kernels are soft and chewy and there is no risk for harming teeth.

ECONOMIC VALUES

• The high water binding capacity significantly increases the dough yield and therefore saves the producer money.

• The cereals are heat-treated in a completely natural process, which considerably cuts down production time as no scalding of the grains is then required.

DISCOVER THE RANGE OF NATURAL AND FUNCTIONAL FLOURS & GRAINS

TTT products are avaliable in three grades: flour, groats and cut (choppped) kernels.

These, together with the correct amount of liquid, are added to the unchanged original recipe.

Flour 0,16 mm – M160

Groats 1,5 mm – G1500

Cut kernels 3 mm – S3000

Read and download the full folder here.

Welcome to contact us for more information and guidance on how our functional grains and flours can help you succeed in baking.

* According to market researcher companies Haystack and Mintel. Mintel’s definition of a natural claim is: No additives/preservatives, GMO-free, organic, wholegrain and all-natural products.